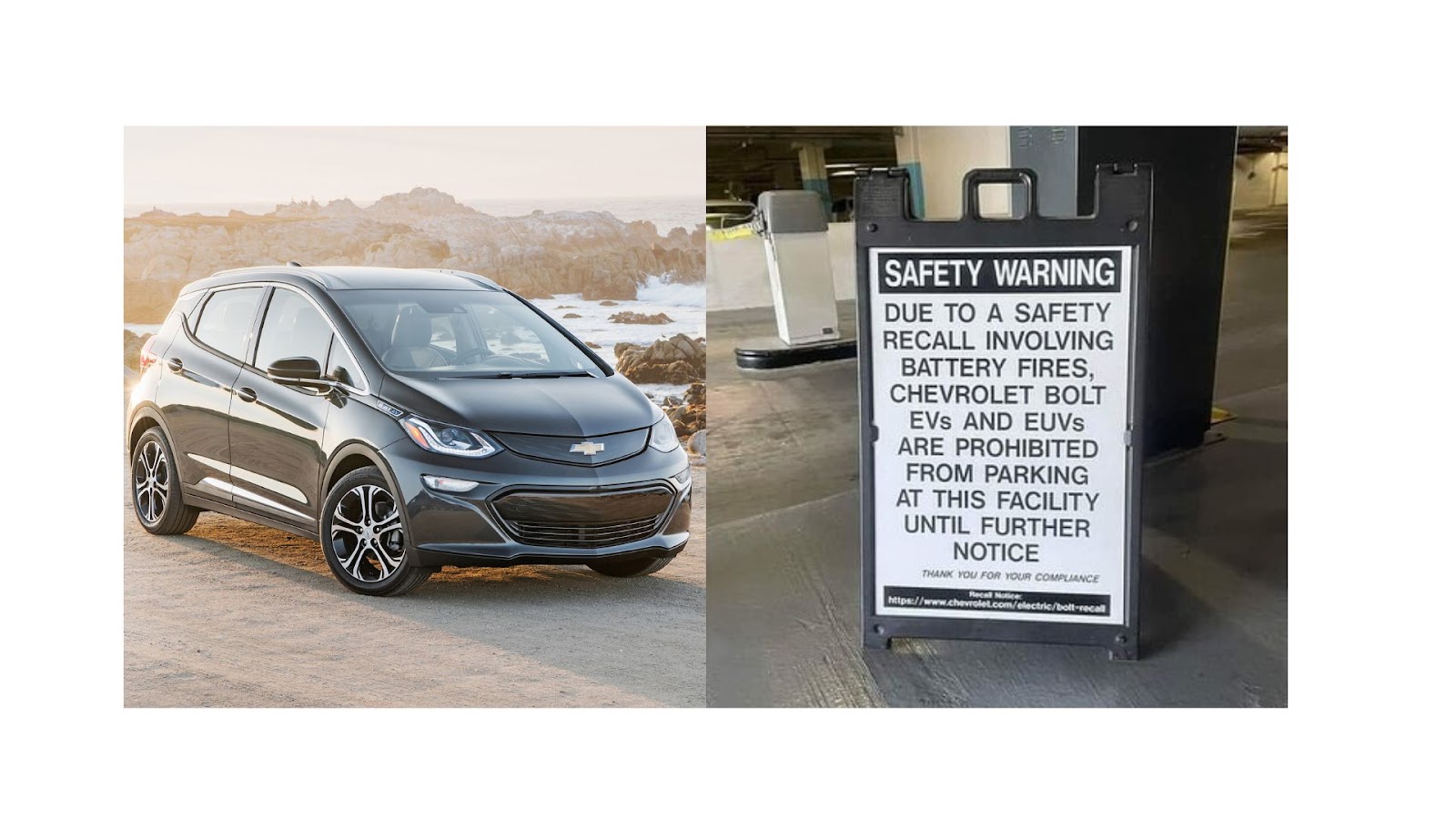

I used to own a Chevy Bolt. Sparky was its name, and it was a high-quality commuter car. One day, a couple of years into ownership, a battery defect caused Bolts to catch fire unexpectedly, and my office garage put up a sign saying that Bolts were no longer allowed in the building. Sparky, now garageless, was very sad.

Electrification has the significant potential to mitigate emissions and decarbonize energy supply chains, making it an important strategy for reaching net zero goals. However, doing so requires high-quality, affordable, and powerful batteries. As my Bolt story shows, for any complex engineered product to reach mainstream production levels and adoption, a robust quality control system is required. Sadly, Sparky will not drive the electrification revolution.

The same was true for the Semiconductor market, where companies like KLA (nearly $10B in revenue and a $100B market cap) enabled the industry to increase yields and improve quality with a suite of monitoring, inspection, and review tools that are now used throughout the chip fabrication process.

As a result, and in addition to the company fitting squarely within our AI-infused complex systems thesis, when Jeff Peters of Ibex Mobility introduced us to the team from Glimpse, we were immediately attracted to the investment opportunity. The three founders – Peter Attia, Patrick Herring, and Eric Moch have a combined 25 years in the Li-ion battery industry, including deep industry (Tesla and Toyota) and academic (Stanford and Harvard PhDs) expertise.

(Left to right: Patrick, Peter, and Eric)

Through this first-hand experience, they realized that the lack of adequate battery quality inspection technology was holding back the industry and our electrified future; preventing the ramp-up of Gigafactories; costing the industry billions in the form of lower yields and field-found defects; and leaving Sparky and I in the dust (of on-street parking).

The Glimpse team leveraged their domain understanding to design from the ground up a high-throughput, high-accuracy, battery quality inspection platform optimized for high-volume battery production and battery assembly environments. The company’s platform marries CT scanners, which they saw the power of in a lab setting at Tesla, with a modern AI-powered analytical software stack and data pipeline to drive unprecedented customer results.

We closed a seed round alongside Ibex Mobility in 2023, and today (ahead of schedule), the company is launching with paying customers in production. If you are intrigued as to what the future of battery quality inspection looks like at scale, they also released into the public domain a dataset of 1,000 batteries that were scanned and processed by the Glimpse technology, which can be found in their portal here.

We are thrilled to back this talented team, tackling a hard and important problem that will help drive a safe and rapid transition to an electrified future and make Sparky (RIP) happy again.